Eddy Current Inspection

Eddy Current Inspection is an electromagnetic technique used for conductive materials to detect surface and near surface defects. This inspection method is sensitive to small cracks and other flaws. It is used to inspect parts of complex shape and size, gives immediate results and is widely used within the commercial, military, petrochemical, aircraft and aerospace industries.

EDDY CURRENT INSPECTION SERVICES INCLUDE:

- Flaw Detection

- Stringers, Fatigue Induced Cracks, Inclusions, and Corrosion

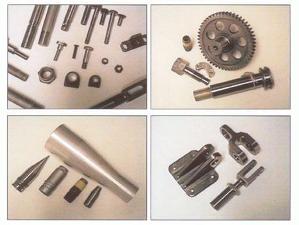

Nuts and Bolts: Threads, Shank, Head, Rolled, Machined

Ball screws: inside Bore and outer Bearing Surface

Machined parts: Bolt Holes, Slots, and Corners

- Stringers, Fatigue Induced Cracks, Inclusions, and Corrosion

- Conductivity Measurements - Alloy Sorting, Hardness Correlation, Corrosion Control

- Coating Thickness Measurements - Primers, Paint, Plating, Anodizing, Plasma Spray

- Material Thickness Measurements - Thin Tubing, Sheet Stock

- Rapid Sorting of Small Components - Flaws, Size Variations, Material Variation

- Technique/Procedure Development

Inspection Personnel qualified and certified to NAS410, BSS7698 and SNT-TC-1A

Approved by U.S. Military and Prime Aircraft/Aerospace Contractors