Ultrasonic Inspection

Ultrasonic Testing (UT) uses high frequency sound energy to conduct examinations and make measurements. It is used to inspect critical materials for flaw detection/evaluation, dimensional measurements, material characterization, and more. QMI provides ultrasonic inspection for a variety of engineered materials such as:

| Aging Aircraft | Castings/Forgings | Honeycomb Core |

| Alloys | Ceramics | Metal Laminates |

| Barstock/Tubing | Multi-Layer Circuit Boards | Nomex |

| Bonded Structures | Composite Laminates | Welds |

| Carbon | Foam Core | Wood Laminates |

ULTRASONIC INSPECTION SERVICES INCLUDE:

- C-Scan Inspection

- Through-Transmission and Pulse Echo

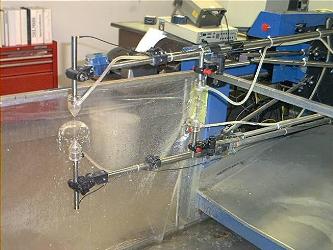

- Immersion and Water-Jet (Squirter)

- Dry-Coupled

- Airscan® Inspection (Air-Coupled Ultrasonics)

- Manual A-Scan Inspection (Contact)

- Thickness Gauging

- Technique/Procedure Development

NADCAP Accredited

Inspection Personnel qualified and certified to NAS410, BSS7698 and SNT-TC-1A

Approved by U.S. Military and Prime Aircraft/Aerospace Contractors